- Industries we serve

Industry Highlights

Our proprietary rubber compounds, precision machining, and engineering expertise ensure optimal performance, regardless of industry-specific demands.

- Detailed Overview

Textile Industry

The essential requirements for textile industry roll coverings are its chemical resistance and stability, resistance against abrasion and durability.

At TKR we custom formulate roll covers as per industry requirements and specifications. Our roll covers deliver high performance and their long life and durability meet your concerns for cost effectiveness.

Depending on your specific application, we can help you determine roll covering best suitable to give you longest wear. Because our more durable rollers maintain their hardness longer and are less affected by swell, they will increase your run time and decrease your down time.

In regards to textile industry we are supplying rollers to all parts of India thereby encompassing majority of vertically integrated textiles units.

1. Rolls for continuous dyeing ranges

2. Rolls for continuous bleaching ranges

3. Rolls for pre-treatment ranges

4. Rolls for continuous washing ranges

5. Rolls for mercerizers

6. Rolls for stenter mangle

7. Rolls for sizing machines

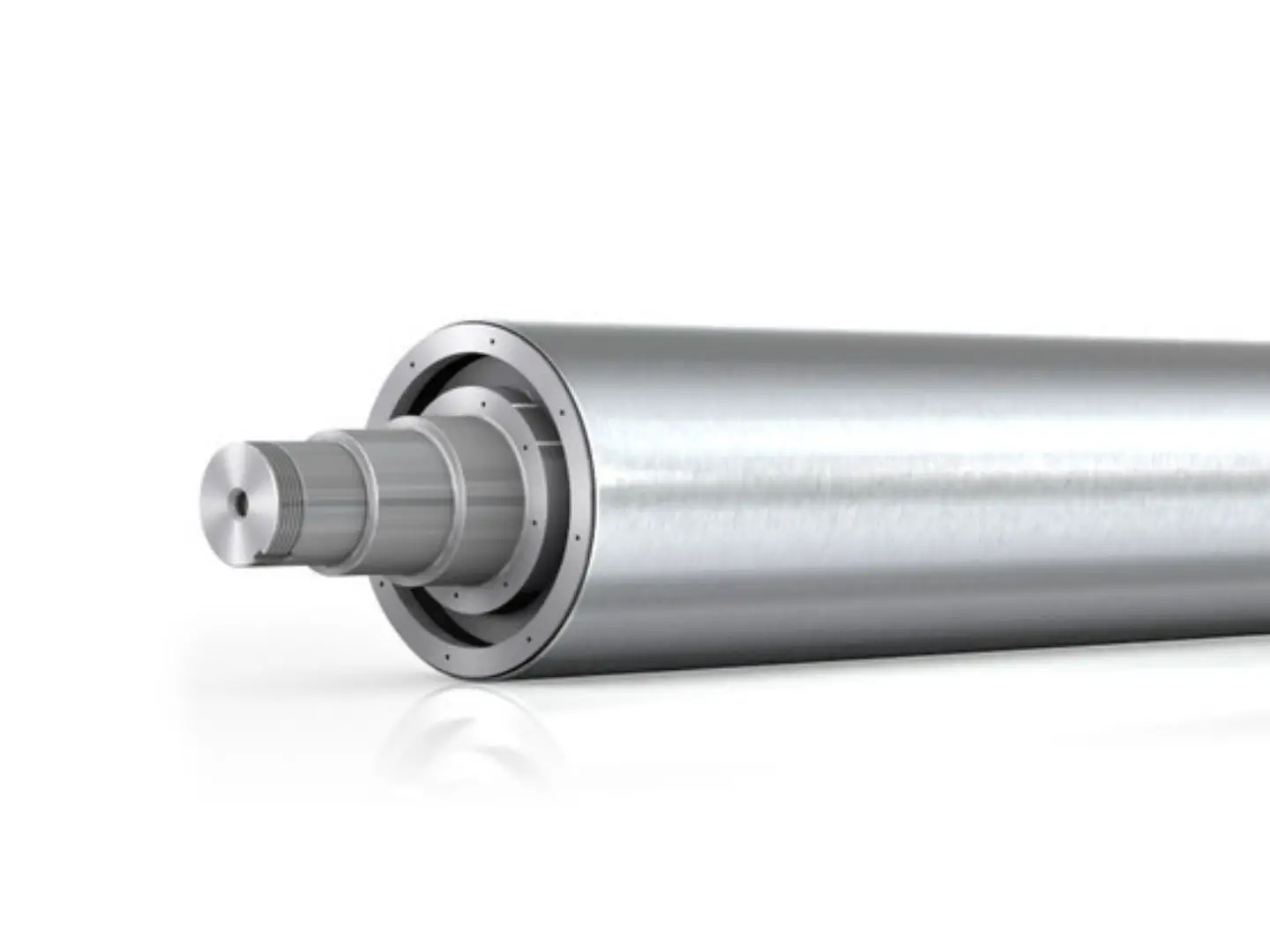

8. SS Guide Rollers

9. Scrolls rolls

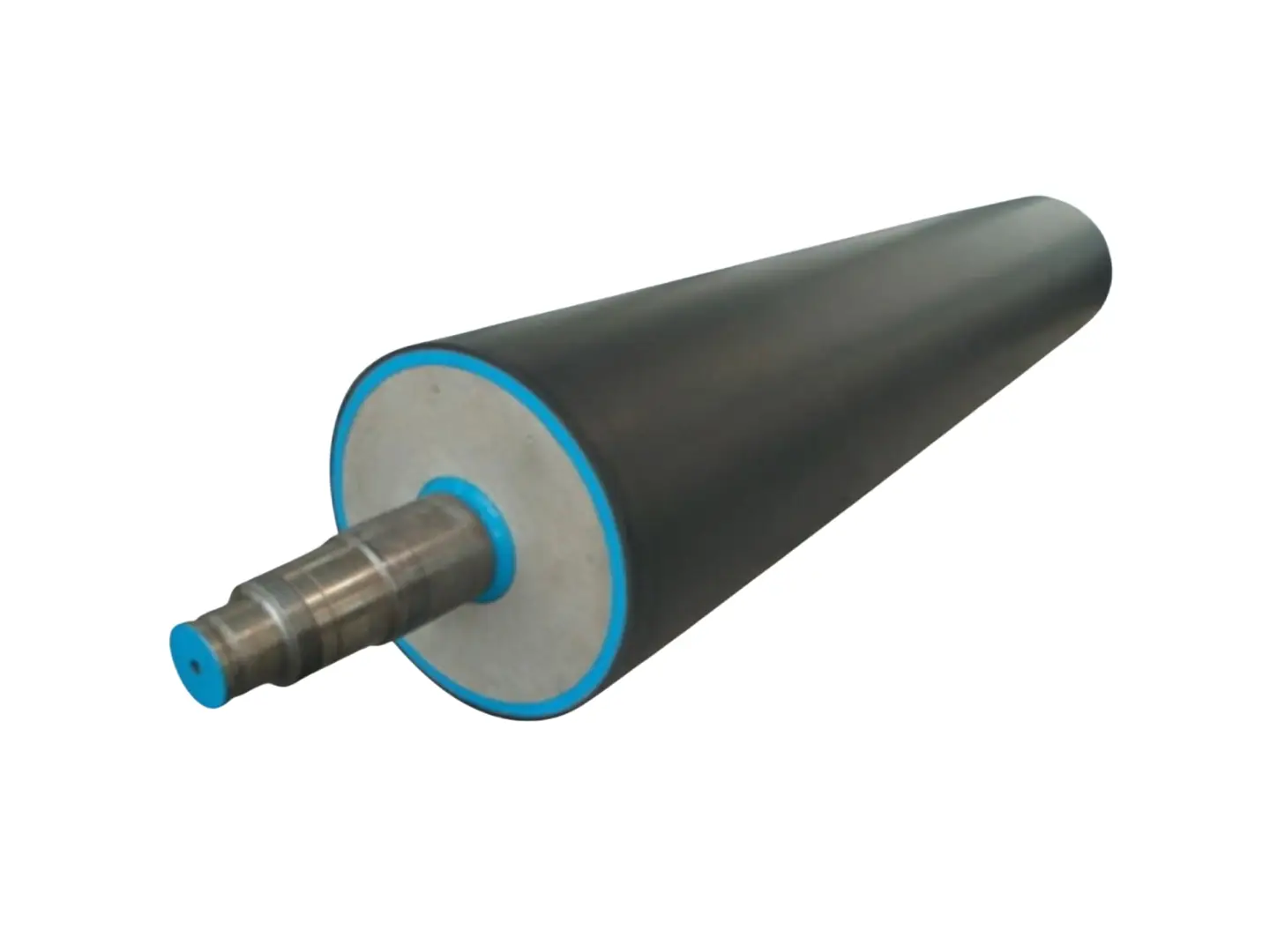

10. Rubber expander / Spreader rolls

- Detailed Overview

Paper Manufacturing

We are one of leading suppliers for rubber rollers to paper industry. Our roll coverings ensure improved sheet quality and increased productivity.

From forming to finishing, TKR’s precision-engineered rubber and ebonite rollers keep paper machines running smoother, faster, and longer- delivering cleaner sheets, fewer breaks, and lower maintenance costs.

1. Top/Bottom Press Roll

2. MG Touch Roll

3. Mould Couch Roll

4. Felt Roll

5. Wire Roll

6. Breast Roll

7. Bow/Spreader Rollers

8. Rubber coated guide rollers & MS rollers

- Detailed Overview

Steel & Metal Processing

TKR supplies rugged roll covers engineered to endure the heat, scale, oils, and heavy loads of steel-mill lines, keeping production steady and maintenance costs low.

Bridle / Tension Rollers – high-grip NR (Natural Rubber) or NBR (Nitrile Butadiene Rubber) covers maintain coil tension; example: hot-strip run-out tables.

Pinch & Wrapper Rolls – hard EPDM (Ethylene Propylene Diene Monomer) or ebonite surfaces resist ≥ 200 °C, preventing slip during coiling.

Squeeze / Deflector Guide Rolls – chemically resistant polyurethane eliminates oil carry-over in pickling and galvanizing lines.

- Detailed Overview

Leather Processing

TKR delivers chemical-, moisture-, and abrasion-resistant rubber rollers purpose-built for every stage of leather processing, ensuring consistent hide finish, fewer roll changes, and steadier throughput.

We supply:

Rubber Rolls for Setting Machines

Rubber Rolls for Sammying Machines

Rubber Rolls for Buffing Machines

Rubber Rolls for Fleshing Machines

- Detailed Overview

Plywood Manufacturing

TKR produces high quality roll covers specially designed to meet the chemical, thermal and mechanical requirements of the plywood industry.

We supply:

Rubber Rolls for Glue Spreader Machine

Rubber Rolls for Pilling Machine

Ebonite Rolls & Steel Guide Rolls

- Detailed Overview

Packaging & Printing

With decades of materials know-how and precision engineering, TKR supplies high-performance rubber and ebonite rollers that meet the demanding speed, pressure, and solvent conditions of today’s packaging and printing lines. Our custom-formulated roll coverings keep sheets tracking true, inks transferring cleanly, and downtime to a minimum, no matter the application. We supply rolls and roll covering for the following sectors.